The need for strong, lightweight materials to fabricate parts and components in critical industries has led to rapid advancements in 3D weaving technology. This has enabled manufacturers to increasingly use composites in place of traditional metals and plastics.

Composites based on 3D woven fabrics can often be used as lightweight alternatives to steel and aluminum without sacrificing strength or durability, making them ideal for aerospace, heavy industrial, marine, transportation, and myriad other applications.

A wide variety of fibers can be used in 3D woven fabrics to produce advanced composites. Some of the fiber types commonly used in composites include:

- Carbon

- Glass

- Polymers

- Ceramics

- Metals

Industry Applications

Numerous industries utilize advanced composites manufactured via 3D weaving, such as:

Aerospace

At Tex Tech, we are exploring a variety of solutions for the aerospace sector, including hybrid materials such as fabrics that include Kevlar, S-glass, or carbon. We’re also exploring the possibility of fabricating common preforms, such as I-shaped, H-shaped, and T-shaped preforms.

Composites have also become integral in the fabrication of aerospace tooling. This tooling often has to undergo repetitive autoclaving, so it must be able to withstand repeated cycles of high temperatures. Composite tooling offers a more affordable means to produce tooling for high-volume production of aerospace parts and components when compared to more traditional metal tooling. Using the thicker, fast infusing 3D woven fabrics and preforms can both speed the manufacture of the tooling and make it tougher, more durable.

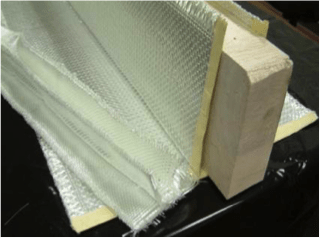

Construction

The construction sector has turned to composites as a means to provide strong structural support without the heavy weights or high corrosion risk of metals. Architects and designers, in particular, appreciate the versatility and reduced costs associated with composites for construction.

Tex Tech offers pilings and 3D composite mats for use in the commercial construction market. We’re also working on developing composite I-beams, as well as C-shapes and various angles.

Industrial

The innate corrosion resistance of composites makes them an ideal material choice for many industries with harsh operating environments, such as chemical production, power generation, and oil and gas. These sectors and many others have turned to composite fibers for their longevity and superior performance under conditions that other materials simply can’t handle.

Tex Tech currently offers composite solutions used in electric power generation, chemical tanks, water tanks, and fracking, among others. We’re always investigating new ways to use 3D fabric-based composites to replace steel or other metals in harsh operating environments, such as in cooling towers used in power generation.

Infrastructure

The United States is facing an infrastructure crisis, leading to demand for innovative and affordable new material options for components. Composites have gained particular traction in bridges, where composite wraps are frequently used for repair and refurbishment of existing structures. While the applications for 3D composite fabrics are still in development for infrastructure, there is much room for growth in this area.

Transportation

Across transportation vehicles and modes, one fact remains true: Lighter vehicles use less fuel. 3D composites have made their way into automobiles, buses, trains, and more as a means to decrease the weight of vehicles and improve fuel efficiency. For example, Tex Tech is currently exploring the possibility of creating 3D composite railcars and truck trailers to significantly reduce weight for commercial transportation applications.

Marine

The boat manufacturing sector relies on 3D composites as a means to fabricate marine components that can resist the corrosive effects of constant water exposure. The fast lay-up, higher strength, and toughness of composites based on 3D woven fabrics also makes them ideal for marine applications.

At Tex Tech, we’ve served the marine industry with the development of a glass Z yarn/carbon hybrid ideal for tooling carbon boat hulls and other carbon parts.

Benefits of 3D Weaving

3D weaving technology enables manufacturers to produce materials and components that have:

- Improved durability

- Increased strength

- Superior joining capabilities

- No risk of delamination

- Lower labor costs

- Customizable thickness

These fabrics are created using specially designed 3D looms. The resulting un-crimped yarn paths eliminate potential weaknesses in the 3D material, as tensile and compressive strengths may be compromised if the fibers are bent or damaged. Additionally, Z-fibers reinforce the fabric by binding it from top to bottom, increasing the ultimate toughness of the material.

Multiple features may be implemented as required, as 3D fabric designs are highly customizable. For example, an item fabricated from 3D composites may offer increased shear strength in one section and axial stiffness elsewhere as required by the application.

The Future of 3D Weaving Technology

Material scientists continue to explore ways to develop 3D weaving technology and produce more advanced composites that can successfully replace traditional materials with stronger, lighter alternatives. 3D woven fabric has already found a permanent place as a lightweight alternative to metal in many critical industries.