Ablative materials are used in thermal protection systems (TPS) to protect vehicles from extreme heat and other harsh environmental conditions during flight. While it’s common to use ablative cork, this isn’t necessarily the best or most efficient option for every application. On the other hand, high-performance products like Q Shield can maintain their ablative properties during launch, reentry, and subsequent launches, offering unique benefits that set them apart from traditional cork options.

Q Shield TPS consists of multiple layers, including a high-temperature-resistant top coating and an underlying layer of thermal insulation material. It features a lightweight construction and pre-painted exterior, supporting a wide range of missions and applications. Learn more about Q Shield and how it compares to cork materials in this brief guide.

Is Cork Ablative?

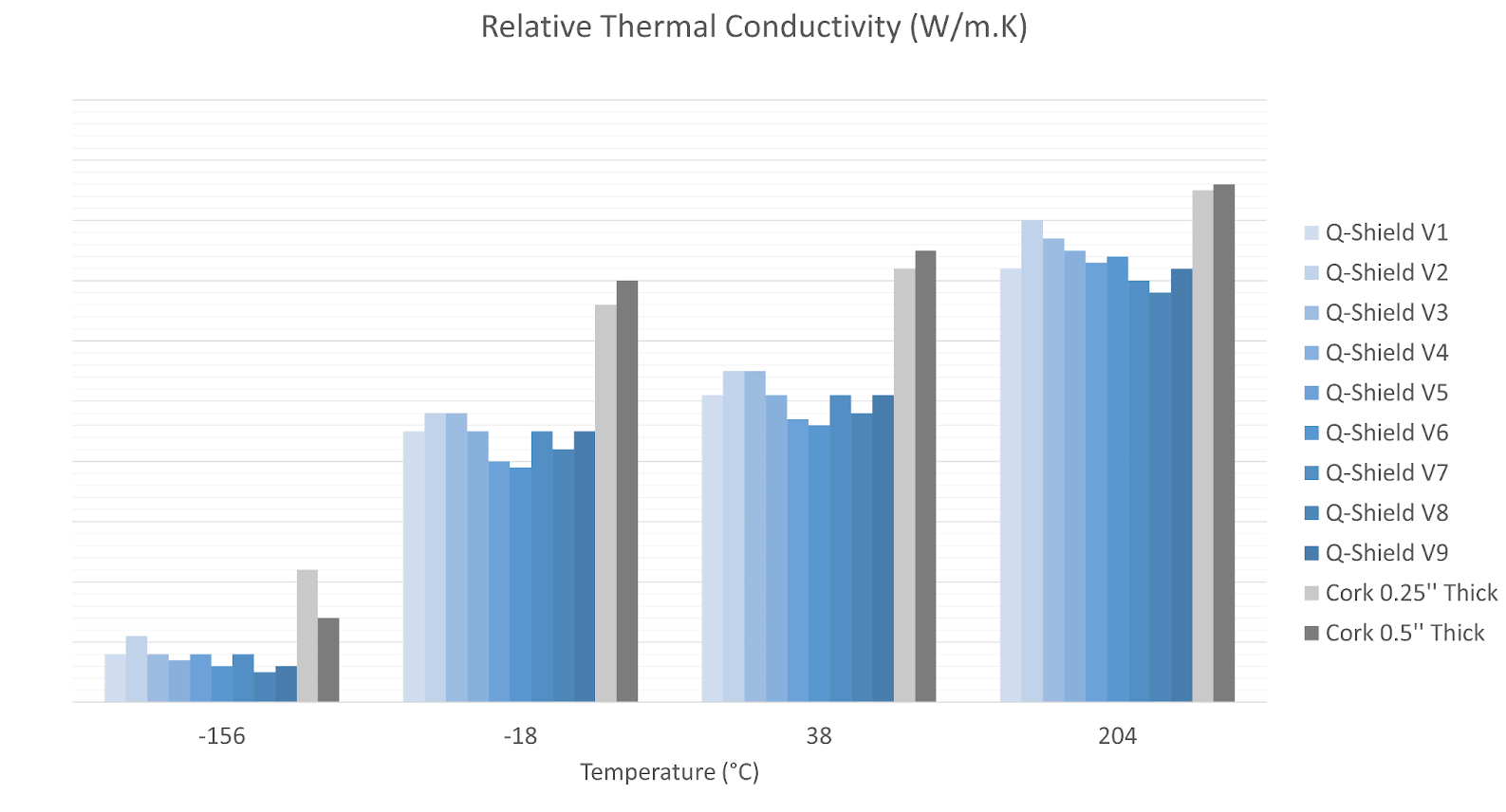

Cork is a common material choice in many applications due to its ablative properties. The cells in cork consist of small irregular-shaped prisms filled with air, allowing it to absorb a large amount of heat. P50 cork specifically comprises a blend of phenolic binders and ground cork that burns slowly under ignition while insulating the inner material. This material typically comes in small sheets of varying thicknesses.

The benefits of ablative cork include:

- Reduced thermal conductivity

- Low intercellular radiation

- No intercellular convection

- Ease of cutting and machining

While materials like P50 cork have been used historically, more modern solutions such as Q Shield offer many advantages for covering large areas or curved surfaces.

How Q Shield Surpasses Cork for TPS

Q Shield outperforms traditional cork materials in a number of areas while maintaining critical ablative and thermal properties. It is designed to endure multiple missions, protecting the vehicle from extreme heat, abrasion, and electrical disruption during launch and reentry. The durability of Q Shield also minimizes turnaround times, allowing you to quickly prepare for the next mission.

Q Shield’s reusability saves you money in a number of ways, including:

- Reduced launch costs

- Smaller fleets of reusable vehicles

- Increased overall fleet profitability

Additionally, Q Shield is fully customizable and can include a pre-painted, ready-for-launch surface coating. This coating provides added benefits such as reduced labor and faster installation.

Q Shield vs. Cork: Choosing the Best Material for Your Project

Ultimately, the material you choose depends on your team’s unique requirements. While applications often use P50 cork because of its machinability and low thermal conductivity, Q Shield offers certain advantages that you won’t find with cork. The following are some of the top benefits that can make it a superior alternative:

- A range of customizable features and surface coatings

- Reliable thermal protection over several missions

- Minimized labor

- Pre-painted, ready-for-launch surface coatings that eliminate the need for long cure times

These highly durable reusable thermal protection materials allow for a smaller, more profitable fleet with lower launch costs.

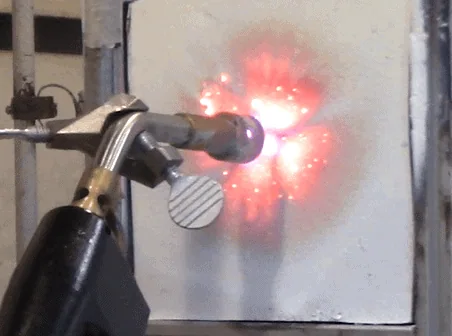

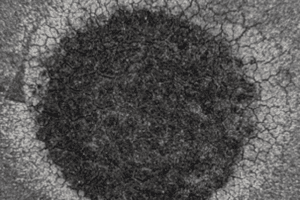

See the below images to see the how Q Shield remains intact after torch tests at 836 degrees Fahrenheit and 2,106 degrees Fahrenheit

Learn More About Q Shield

TexTech provides a range of innovative products, including thermal protection systems, high-performance textiles, and heat shields. Our Q Shield TPS products are designed to protect vehicles from abrasion, heat, electrical disruption, and more. We can customize your TPS solution to meet a range of application-specific requirements, allowing you to get the most from your fleets.

Contact us to learn more about Q Shield or request a quote for a custom solution today.