At Tex Tech Industries, we manufacture a wide range of high-performance, expertly designed textile materials for use in various applications, from personal and product protection to industrial.

Working closely with customers to design reliable, long-lasting solutions, woven, non-woven, and coated alike, Tex Tech has developed an expansive catalog of unique high-performance textiles. We integrate several types of fiber into our high-performance textiles, including meta-aramids such as Nomex, a variety of oxidized polyacrylonitriles (Pre-Ox Pan) such as Pyron or Panox, silica fibers, and para-aramids (p-aramids) such as Kevlar. By blending these and other specialty fibers, Tex Tech can create materials that are uniquely suited to all kinds of applications and specifications.

These fabrics are supplied to our customers, who further process them through their own production facilities. Processing may include carbonization, graphitization, and/or phenolic coating. These technical fabrics could ultimately be produced into final products to be used in wide and varied final applications including chlor-alkali, fuel cell, and water absorption applications.

High-Performance Textiles: Swellable Water-Blocking Yarns

Modern-day industry often necessitates the use of cables and sensitive electronics in challenging environments. To combat the risk of mechanical or rodent breaks in cables, which could result in the ingress of water channeling into cables, various layers and sublayers within the cables can be protected with water-blocking yarns.

Tex Tech manufactures OASIS Super Absorbent yarns in a range of long-staple ring-spun and long-staple wrap-spun styles. These proprietary blends of fibers are designed to absorb moisture immediately, swelling as they do to prevent more moisture from entering a cable or other electronic product.

Aside from their industry-leading absorption and swelling properties, OASIS products also offer more consistent performance than similar products. Featuring enhanced strength properties, OASIS SAF yarn solutions are also cleaner, generating less dust, and are available in a range of diameters and sizes. Regarding our swellable yarn product, Tex Tech produces the OASIS Super Absorbent yarn itself.

High-Performance Textiles: Cured-in-Place Pipe Lining (CIPP)

Over time, pipes suffer from wear or develop cracks. Should any previously installed lining fail, piping systems can experience leaks. CIPP serves as an additional protective layer on installed piping to address such potential occurrences. Available as an immediate solution, CIPP is applicable in water or storm sewer mains, municipal or sanitary systems, culverts, and most related environments and high-pressure systems. It can effectively repair short or long piping sections, meaning that you won’t have to tear out a full pipe installation to fix a single portion. With the assistance of heat or ultraviolet light, technicians can cure a smooth layer of CIPP where you need it for fast yet durable results.

High-Performance Textiles: REFRASIL®

REFRASIL® silica textiles are a suitable alternative for asbestos. These continuous filament silica textiles have an amorphous structure and offer a range of benefits, including:

- Exceptional thermal resistance

- Fire resistance

- Superior resilience

- Flexibility up to 1800° F

- Cost-effectiveness

REFRASIL® textiles are available in a variety of types, such as fabrics, rope gaskets, tapes, and yarns. They also have multiple standard and specialty coating options.

High-Performance Textiles: Lithium Battery Fire Suppression Materials

The efficient recharging capabilities and long-term reliability of lithium-ion batteries make them a dependable choice as a power source. They provide energy for everything from smartphones, laptops, and cameras to medical equipment, EVs, and solar storage devices, with their applications growing by the day. However, defective or damaged lithium batteries present a known fire risk, so it’s important to understand how to handle such a hazard when it occurs.

As an industry leader in flame-retardant fabrics and related materials, Tex Tech Industries offers fire suppression material solutions for lithium battery applications.

High-Performance Textiles: Chlor-Alkali

The chlor-alkali process uses electrolysis to produce critical chemicals for industrial processes, and within the production process, a Tex Tech woven fabric with stretch-broken Pre-Ox Pan fibers that has been carbonized is used in the non-porous membrane. Tex Tech fabrics are a component within the chlor-alikali process plant.

High-Performance Textiles: Fuel Cell Materials

Fuel cells, not to be confused with batteries, are devices that convert chemical energy from an external fuel source into electrical energy. Hydrogen is the most commonly used type of fuel in this process, while water is the most common type of waste.

Within fuel cells are gas diffusion layers, and Tex Tech manufactures both woven and non-woven fabrics with Pre-Ox Pan that can be utilized in these product areas. Pre-Ox Pan is already oxidized and is further treated through a carbonization process. Tex Tech fabrics are a component within the fuel cell assembly.

High-Performance Textiles: Applications

Tex Tech Industries has been a leader in the technical textile industry for more than 100 years. During that time, we have devoted ourselves to continual research and development of new textile and fiber solutions; today, we manufacture more than 7,000 products, including a wide range of high-performance materials. With manufacturing facilities located in the US, Europe, and Asia, we are well-positioned to support your needs.

High-performance textiles from Tex Tech are used in a huge variety of applications, including:

Mass-transit bus and train seating

Automotive aftermarket

Welding

Offshore drilling

Shipbuilding

Thermal insulation

A&D

Medical

Recreational

High-Performance Textiles From Tex Tech Industries

To learn more about high-performance materials from Tex Tech Industries — including our heat- and flame-resistant materials, chlor-alkali precursor materials, fuel cell materials, and water absorption material options — contact us or request a quote today.

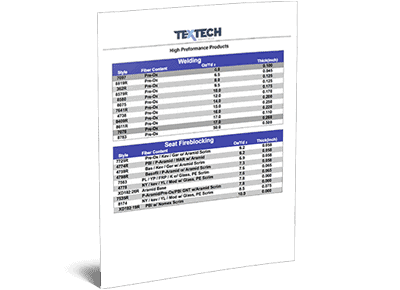

View the High-Performance Products Data Sheet

Download a copy of our data sheet to learn more about necessary weights, thicknesses, and style numbers for materials such as Kevlar, Pre-Ox, Aramid.

Download Now