Non-woven fabrics are flat, porous sheets or web-structured materials created through the bonding of fibers or perforation of films using chemical, mechanical, or thermal processes. Unlike woven materials, non-woven fabrics do not require weaving or knitting, so the component fibers do not need to be converted into yarn first.

Non-wovens are available in a wide range of materials and designs and can be enhanced to offer numerous advantages over woven fabrics, including:

- Increased Absorbency

- Improved Filtering

- Flame Retardancy

- Liquid Repellency

- Sterility and Bacterial Barrier

- Strength and Resilience

- Softness and Flexibility

- Improved Washability

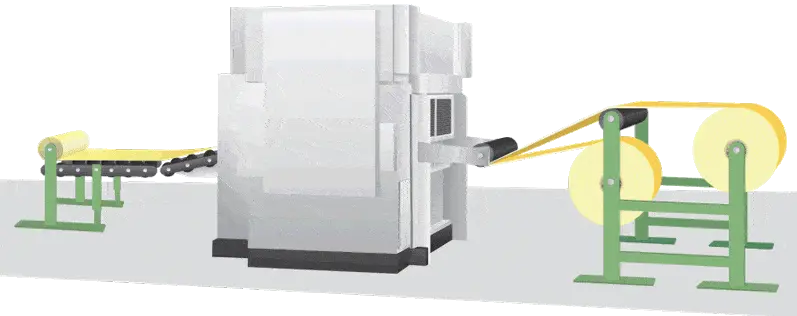

Needle-Punched Non-Wovens

Needle-punched non-woven fabrics are created by carding loose fibers into a felt-like batting that is then punched together using barbed felting needles. The process can be used to create fabrics of varying thickness and strength, and the needling process often leaves a pattern of holes on the surface that varies depending on the number of needles in the needle board, needle size, punching density, and type of fiber.