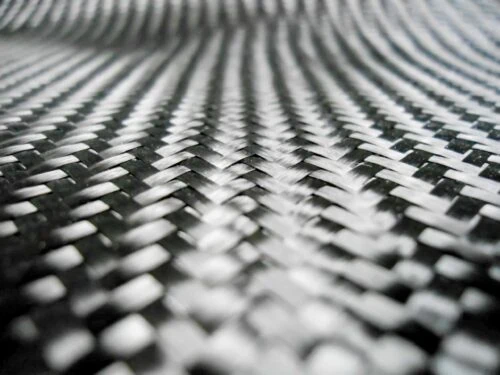

High-Performance Textiles

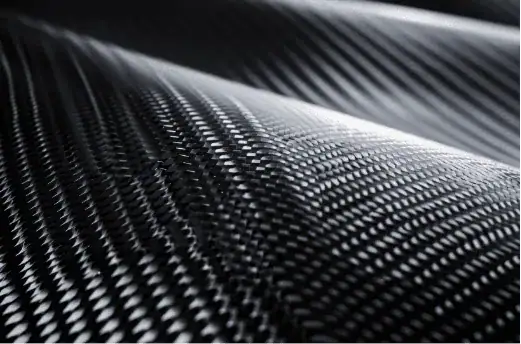

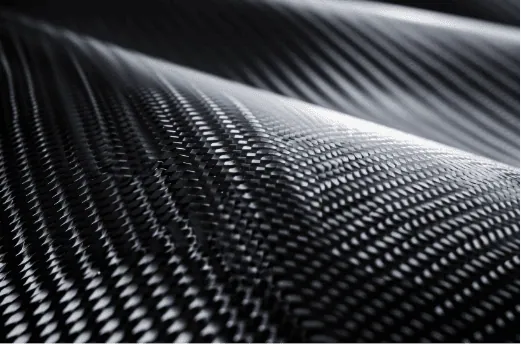

At Tex Tech Industries, we manufacture a broad range of expertly designed, high-performance textile materials for the following applications:

- A&D

- Medical

- Shipbuilding

- Automotive Aftermarket

- Offshore Drilling

- Thermal Insulation

- Mass-Transit Train and Bus Seating

- Recreational

- Welding

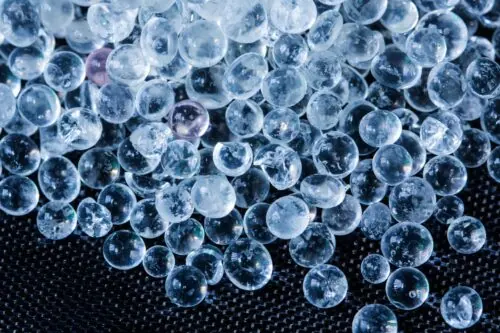

We work closely with our clients to design long-lasting, reliable solutions, integrating several quality fibers into our high-performance textiles.