3D Woven Fabrics

Providing high durability, excellent strength, and innovative joining capabilities, advanced composites based on 3D woven fabrics continue to evolve as technology charges forward. Used in a wide range of industries, including offshore structures, and aerospace, these custom 3D woven materials are valuable in many types of applications.

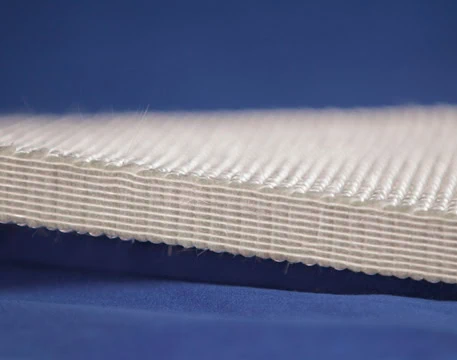

In recent years, 3D woven fabric-based composites have seen major advances and growth. Easier to lay up and infuse, these materials also carry no risk of delamination—a common struggle with 2D woven composites.

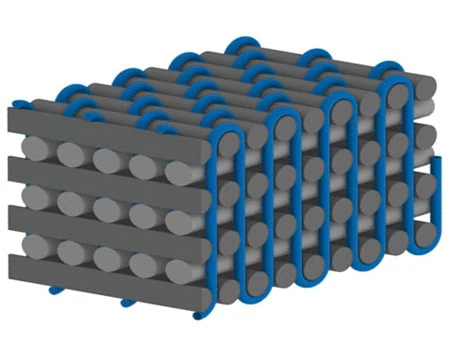

3D Woven Fabric Technology

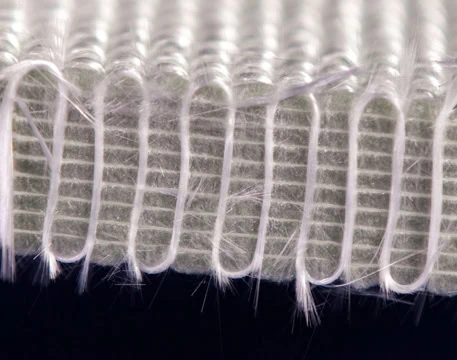

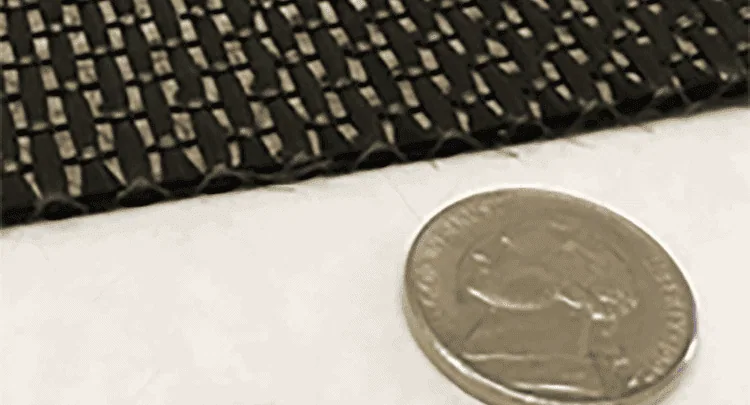

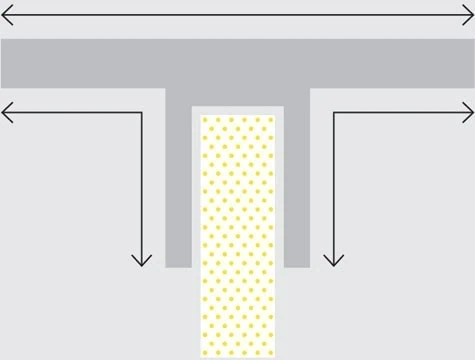

Using specialized weaving systems and looms, the in-plane yarns in Tex Tech’s 3D woven fabrics are produced with uncrimped fibers to eliminate potential weaknesses in the material. The straight fibers in our woven fabrics lack stress-concentrating undulations, resulting in higher-strength products, while Z-fibers provide enhanced toughness and resistance to delamination.

Composites based on 3D woven fabrics also perform well in replacing traditional materials, such as steel, without sacrificing durability or strength. Their high strength-to-weight makes them ideal for industries such as transportation, heavy industrial, and marine.

3D woven fabrics can also be produced with specialty fibers and materials for advanced composite applications such as fireproofing. Tex Tech Industries works with many of these materials, including: