REFRASIL high-temperature silica cloths provide continuous thermal protection from 982°C to 1260°C (1800°F to 2300°F). These textiles are continuous filament, amorphous silica products with the exceptional thermal performance and characteristics of a refractory material.

REFRASIL®: Key Specs and Benefits

REFRASIL textiles have a melt point temperature of approximately 1593°C (2900°F) and a continuous-use design temperature of 982°C (1800°F). REFRASIL is designed to provide exceptional thermal and strength properties while maintaining desirable flexibility up to 982°C (1800°F).

REFRASIL cloths are available in standard offerings such as UC series and pre-shrunk (C series) forms. The cloths can also be treated for abrasion-resistance (AR series) and elevated continuous temperatures of up to 1260 °C (2300 °F) (Irish series).

In addition, the UC series fabrics are available with specialty coatings such as silicone rubber, aluminum foil, pressure sensitive adhesives (PSA), and neoprene rubber.

Features and benefits of REFRASIL cloths include the following:

- Suitable asbestos replacement

- Excellent spark and molten metal shielding

- Highly resilient

- Fire-resistant

- Resists damage from molten metal and radiant heat

- Compatible with most harsh chemicals

- Low halogen content

- High dielectric strength

- Minimal off-gassing

- Low thermal conductivity

- No known health hazards

- Amorphous structure

- Very cost-effective

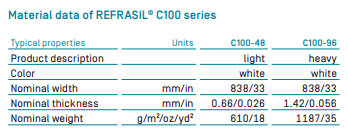

REFRASIL® C100 Series

The REFRASIL C100 series are pre-shrunk cloths that protect up to 982°C (1800°F). They are identified by their pure white color and are used in applications where very low residual thermal shrinkage is desirable. C100 series fabrics are very effective in many heat treatment applications and can be used in various composite applications. They are also often used in aerospace applications, including solid rocket nozzle construction

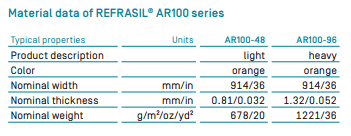

REFRASIL® AR100 Series

The REFRASIL abrasion-resistant fabric (AR100 series) is identified by its distinctive orange color and is coated with a specially formulated coating that makes it more abrasion-resistant than standard UC100 series fabrics. The AR100 series fabrics are recommended for highly rigorous applications subjected to dragging, scraping, tearing, and snagging. The AR100 series fabrics make a great choice for fabricated welding cloths, pads, screens, and personnel protection shields. Although the AR coating begins to degrade near 177 °C (350°F), its thermal and tensile properties continue up to around 982°C (1800°F).

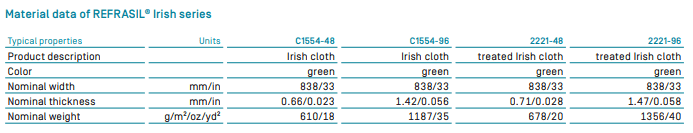

REFRASIL® Irish Series

REFRASIL Irish insulation cloth was developed to extend the temperature range and flexibility characteristics of REFRASIL textiles. The Irish series fabrics are identified by their green color which comes from the special high-temperature treatment. REFRASIL Irish insulation can withstand continuous temperatures up to approximately 1260°C (2300°F) with little or no change in properties. REFRASIL Irish fabrics come in two versions: C1554 is the base Irish coating and 2221 is comprised of C1554 with an additional finish coating for ease of handling and physical integrity during fabricating.

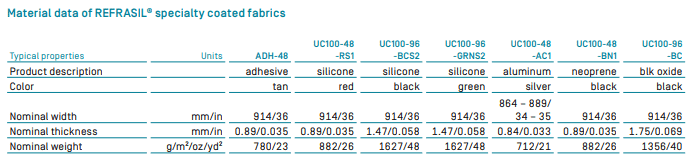

REFRASIL® Specialty Coated Fabrics

REFRASIL standard fabrics (UC100 series) are available with the following coatings: pressure sensitive adhesive (PSA), silicone rubber, aluminum, neoprene, and black ceramic oxide. These coatings are designed to provide special properties to enhance and diversify the exceptional qualities of the REFRASIL standard fabrics. These specialty coatings increase the usability of the fabrics by adding properties such as fabric adhesion, water resistance, heat reflectance, and additional thermal protection.

Coatings are available in various configurations of single and double-sided on all weights of fabrics. The specifications shown below represent only a partial list of product offerings. Additional configurations are available upon request.

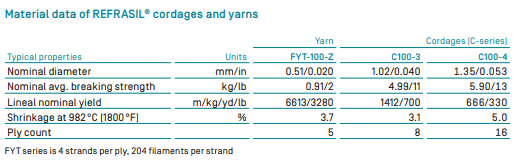

REFRASIL® Cordages and Yarns

REFRASIL cordage and yarn insulate against high temperatures. The fiber is highly porous and does not melt or vaporize until temperatures exceed 1593°C (2900°F). REFRASIL cordage and yarn textiles will operate continuously at temperatures up to 982°C (1800°F) with little or no change in properties because they have been fired at 982°C (1800°F).

These products have excellent resistance to thermal shock, as well as minimal shrinkage at service temperatures. They provide reliable insulation and protection while retaining their original textile characteristics. Cordage and yarn can be braided onto or around thermocouple wires, instrument elements, electrical cables, electrical cable harnesses, and hoses.

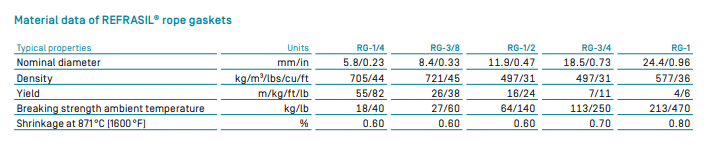

REFRASIL® Rope Gaskets and Sleevings

REFRASIL rope gasket is a dimensionally controlled, high-density, braided, high-silica (96% SiO2) product intended for service temperatures up to 982°C (1800°F). Produced in five sizes – 6.4 mm (0.25″) through 25.4 mm (1″) diameter – REFRASIL rope gasket is braided from texturized yarns, pre-shrunk, and treated with a hydrocarbon finish to improve its abrasion resistance and ease of handling. REFRASIL rope gaskets can be used where compact, dense, high-temperature performance compressive seals are required.

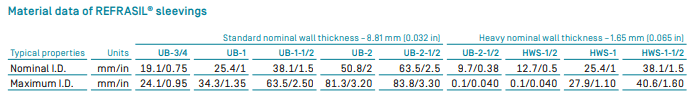

REFRASIL braided sleevings are the solution for efficient, low-maintenance thermal insulation. Absolutely fireproof, these sleevings are also resistant to oxidation and most corrosive solutions and do not degrade in the presence of water. REFRASIL sleevings are available in standard or heavy wall configurations. The looser braid of standard sleeving can accommodate a large variety of diameters. Heavy wall sleevings have a very tight and thicker braid for maximum thermal protection.

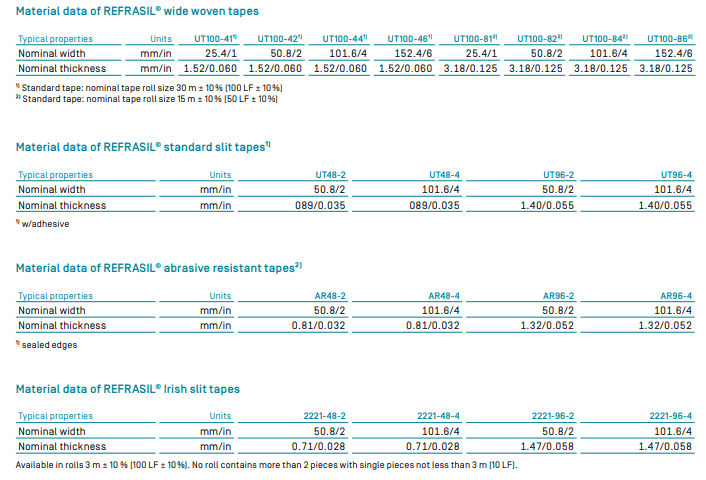

REFRASIL® Slit and Woven Tapes

REFRASIL tapes lower your maintenance cost and provide high-performance protection. In addition, REFRASIL’s excellent dielectric strength makes it an outstanding high-temperature electrical insulator, while its chemical properties contribute to its resistance to oxidation and attack by most corrosive solutions.

Standard REFRASIL tapes are high-silica (>96% SiOB2B) products intended for high-temperature applications with continuous service up to 982°C (1800°F). Woven tape is available in “pre-shrunk” form, which is fired at 982°C (1800°F) to reduce any further shrinkage in the service applications. Wide woven tape in thicknesses of 1.52 mm and 3.18 mm (0.060″ and 0.125″) is produced as standard REFRASIL and is subject to shrinkage when exposed to sustained temperatures above 982°C (1800°F).

Typical applications include:

- Mop curtains for continuous belt furnaces

- Electrical lead wire insulation

- Welding blanket edge and seam binding

- Cooling hose wrap insulation

- Instrumentation wire insulation

- Power cable insulation

Silica Materials: Product from Tex Tech

The versatile line of high-performance woven and non-woven silica fibers from Tex Tech can be tailored to fit the needs of your exact application. Their ability to withstand temperatures up to 1150°C (2102°F) means they are practically fire-resistant. Because of this, they can be used in a wide range of applications across diverse industries, including aerospace, appliance, automotive, defense, railroad, shipbuilding, and many more.

Silica Materials: Custom Capability from Tex Tech

The experts at Tex Tech can custom-tailor our high-performance fabrics to meet your unique requirements. We offer a complete catalog of woven and non-woven materials that can be customized with additional treatments and coatings like silica, making us a full-service supplier for both general and specialized industrial woven and non-woven fabrics.

- Woven: Woven fabrics are created by crossing perpendicular threads over one another in a warp-weft pattern. By weaving the threads together, it creates a highly ordered structure of fibers that resist tearing. At Tex Tech, we use the most advanced weaving technologies to quickly and consistently manufacture tightly woven industrial fabrics and textiles.

- Non-woven: Unlike woven fabrics, non-woven fabrics do not require knitting or webbing. Instead, they are flat, porous sheets or web-structured materials produced by perforating films or bonding fibers using mechanical, chemical, or thermal processes. Our non-woven fabrics are available in numerous designs and materials and can be enhanced to provide various beneficial properties, including flame retardancy, strength, and more.

Learn More About Tex Tech’s REFRASIL® Offerings

At Tex Tech, we offer REFRASIL silica materials that feature a minimum of 96% silica content. They are available in fabrics, tapes, and yarns, as well as pre-shrunk options for applications requiring low thermal shrinkage. These materials can withstand temperatures from 1800 °F to 2300°F, depending on the material selected. Because of their high-performance characteristics, REFRASIL materials are especially well-suited for aerospace applications. For example, they can be used in high-temperature composites as well as fibers for thermal protection systems.

For more information about our REFRASIL product offerings, contact Tex Tech or request a quote today.