New Research in 3D Woven Fabrics Reveals the Potential for Higher Performance Textiles

Leave a CommentFor over 100 years, Tex Tech Industries has committed itself to continuously developing and providing high-performance textiles that meet the requirements of complex and demanding industrial applications. As one of the world’s leading needle and woven fabric manufacturers, our research and development department is well-equipped with an advanced development facility, a drive for innovation, and a thirst for knowledge, which, combined, often result in breakthroughs in the technical textiles sector. For our expert team, the latter two qualities extend beyond the walls of our facility and confines of our products into broader research and development ventures, including international research collaborations focused on high-performance textiles.

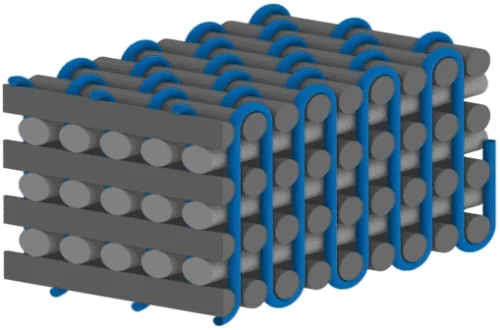

The Positive Potential of Through-thickness Fiber Orientation on Through-thickness Permeability

In late October 2019, one of our Product Development Specialists—Keith Sharp, Ph.D.— co-authored research article[1] on the potential advantages of 3D woven fabrics (3D-WFs) with high through-thickness fiber content for structural applications. Completed with research partners David May, Björn Willenbacher, Jan Semar, and Peter Mitschang from the Institute for Composite Materials (IVW) in Germany, the study tackled the issues of high lay-up requirements and sensitivity to delamination when using 2D textile fabrics and the difficulty impregnating when using thicker traditional 3D woven fabrics. The team believed that by integrating through-thickness oriented fibers in 3D woven fabrics, they could achieve more promising results from through-thickness permeability tests.

Testing the Theory

To test their theory, they measured the permeability of several glass fiber textiles, four of which were 3D woven fabrics and two of which—a 2D non-crimp fabric and 2D woven fabric—served as benchmarks. These tests focused on calculating the relationship, if any, between the particular textile’s areal weight and number of layers to its permeability.

Research Conclusions

From their tests, the team came to a few key conclusions, including:

- Across the board, all 3D woven fabrics tested demonstrated higher through-thickness permeability than both of the 2D benchmarks. Increases were on the order of 10 times as high.

- An increase in the areal weight of the 3D woven fabrics results in an increase in the fabric’s through-thickness permeability.

- The amount of through-thickness oriented fibers significantly influences areal weight and, consequently, through-thickness permeability.

- There was no significant difference in permeability between the 3 layer and the 8 layer 3D woven fabric.

- The above correlations remain true at increasing pressures.

Altogether, these conclusions highlight the potential advantages of 3D woven fabrics and lay the framework for the future development of even higher performance textiles.

To learn more about the potential advantages of using 3D woven fabrics with through-thickness oriented fibers, read the full article here.

[1] D. May, B. Willenbach, J.Semar, K.Sharp, P. Mitschang, “Out-of-plane permeability of 3D-fabrics for composite structures”, The Journal of The Textile Institute pp 1-7; doi:10.1080/00405000.2019.1682759